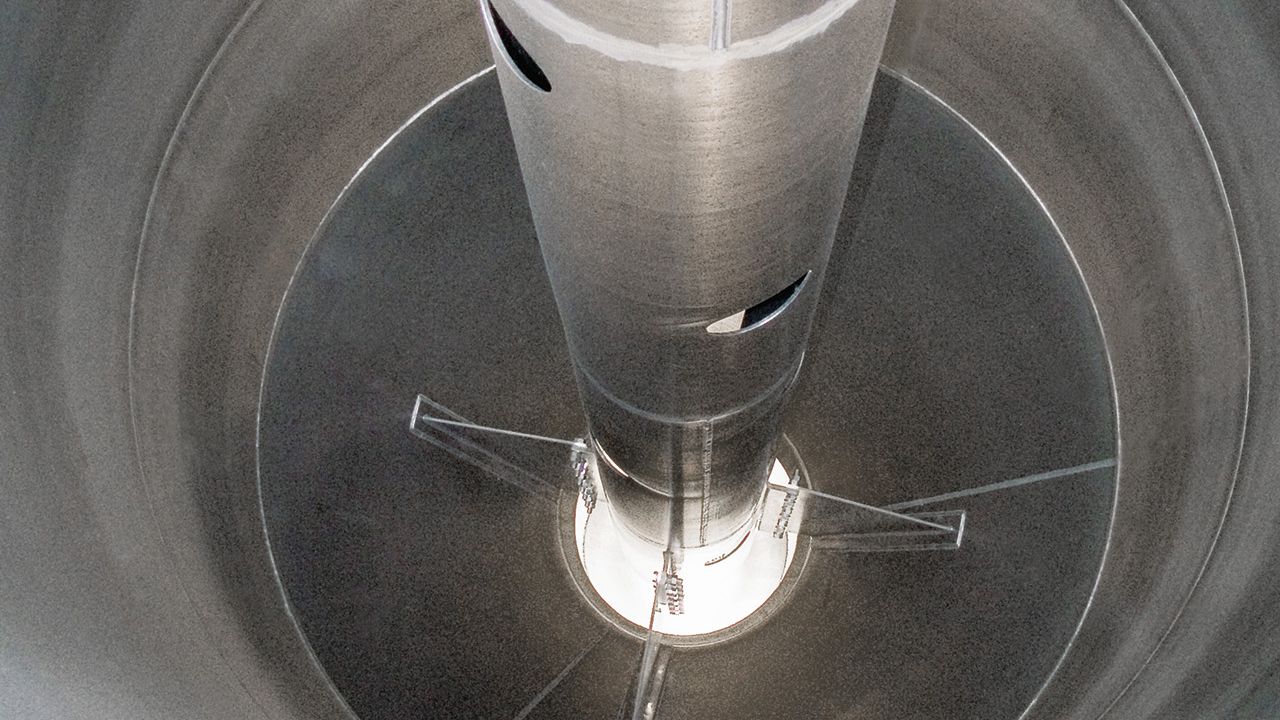

Testing is good - testing at a ratio of 1:1 and under real conditions is better. Whether PE, PP and PS, PET or PVC, your raw materials are in the best hands with us. With our test centers at the Friedrichshafen and Kassel sites, we ensure that your plant is optimally designed for the properties of your raw material - for optimum output in every respect.