For an optimal and more importantly, a reproducible baking result, the basic conditions must remain constant. The temperature of the dough, which is particularly influenced by the raw materials (flour and water), plays an important role in this respect. For this purpose, the Pneumotherm batch process for flour cooling offers economical use.

Industrial bakeries produce a wide range of baked goods made from different types of dough. To ensure that the baked goods are always of consistent quality, doughs should have a certain target temperature after kneading. This is best achieved if the flour and liquids are tempered evenly before processing. Especially when different types of flour are stored in outdoor silos, they must first be brought to the correct temperature before processing.

Determining the optimum dough temperature

For wheat-based doughs, such as those produced with a dough yield of TA165, an optimum dough temperature of approx. 24-26°C is needed. The water temperature normally used for this purpose (tap water temperature) is 10-12°C and the flour being used is at 20°C. With standard intensive kneaders, a high amount of energy is introduced into the dough, so that a large part of the mechanical energy is converted into thermal energy, resulting in a heating of the dough by 8-10°C. Many bakers use a very simple formula to quickly calculate the dough temperature.

The temperature determined in this way is approx. 26 °C and is in the range of the optimum dough temperature for wheat-based doughs.

Unfortunately, the flour temperature is often not at the optimal temperature of 20°C mentioned here. Frequently, especially in the summer months in Central Europe or in Mediterranean countries in general, this temperature is greatly exceeded and can even reach 40°C in some cases. This effect results from the fact that the ambient temperature is very warm and the flour is transported long distances in tankers to the bakery. Moreover, the flour heats up during storage in uninsulated silos, which are directly exposed to the sun. In such cases, not even the use of ice water at 2°C is sufficient, which the above-mentioned baker's formula demonstrates when converted to the temperature values.

The dough temperature of 31°C calculated here is much too high for wheat-based dough. The dough, and consequently the baked goods would not meet the desired quality criteria and would have to be discarded. For this reason, many customers warmer regions of the world use the Pneumotherm batch process for flour cooling, which allows the flour temperature to be cooled down quickly and easily. For use with special doughs, such as doughnuts, where the individual portions are deep-frozen after the fermentation time, the maximum dough temperature should not exceed 16°C. Here, the optimum dough temperature can only be achieved with the help of ice water (2°C) and a flour temperature of 8°C.

In general it can be said that fluctuating and excessively high dough temperatures create a sticky dough that is difficult to process and can lead to undesired baking results. The dough does not rise evenly and the product will vary in size. The different sizes may lead to breakage in the packaging plant.

Cooling process for flours

The most popular cooling methods include lowering the dough temperature with ice, liquid nitrogen or cold laminar air flows. The process using ice shavings or flaked ice has hygienic disadvantages; it is also difficult to regulate. Also, very often the flour is cooled with liquid carbon dioxide before entering the kneading machine. However, the process is considered relatively cost-intensive.

This is why Zeppelin developed the Pneumotherm batch process, which has now proven itself in many applications worldwide. For many years, it was mainly used in warmer regions, such as the Middle East, Asia, Southeast Asia or South America, as well as Italy or Spain. Increasingly, however, there are also plants in Germany. Due to fluctuating temperatures in the external storage silos during the transition from day to night, differences of more than 10 degrees can arise. Also, in plants with external silos, temperatures of more than 30 degrees can easily be reached in the summer, dropping sharply at night.

How does it work?

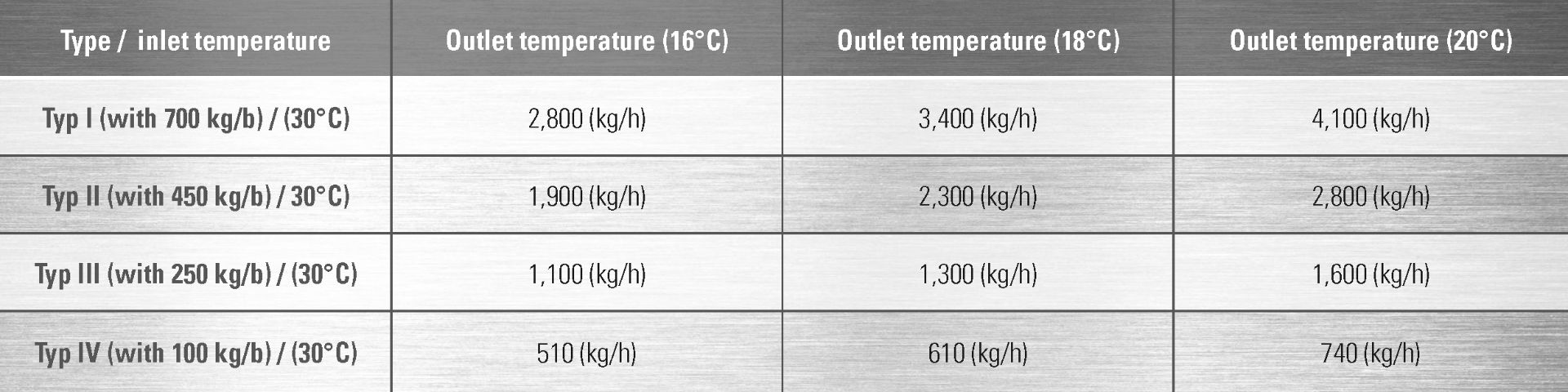

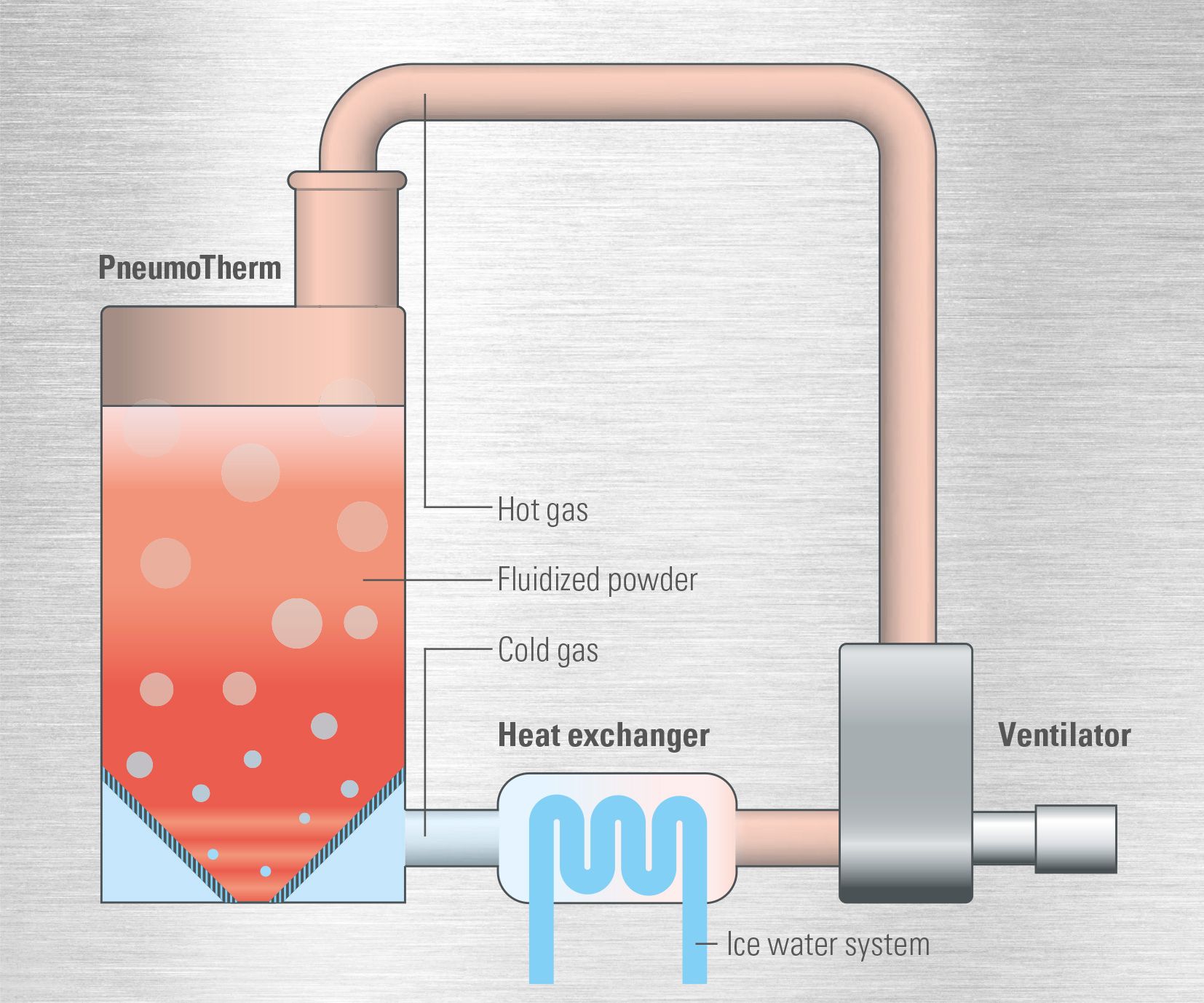

In the Pneumotherm batch process, a certain amount of flour is cooled from an inlet temperature to the desired end temperature (usually 15°C) in a defined time (e.g. 10 minutes). This is done with the aid of a built-in fluidized bed. The flour is weighed in a pre-container and transferred from there to the tempering container. Cold air is then blown in from below through the mixer to create a fluidized bed. This leads to an optimal mixing of flour particles and cold fluidizing air. This air is compressed by a fan, cooled in a heat exchanger and returned to the tempering tank. The fluidizing air is circulated until the desired final temperature of the flour is reached.

The process used minimizes dust pollution of the surroundings and the process is independent of fluctuating ambient conditions. After tempering, the flour is either directly pneumatically conveyed into the target container or discharged into a secondary container so that a temporal decoupling of the downstream systems can be achieved. A new batch is requested via the secondary container in automatic mode as soon as there is enough space for a new batch. For systems that require a low flour temperature down to 5°C, Zeppelin offers special versions featuring a cooling circuit with dual heat exchangers, allowing fluidising air below 0 °C.