Our experts for all questions related to the DVV diverter valve will be happy to assist you personally.

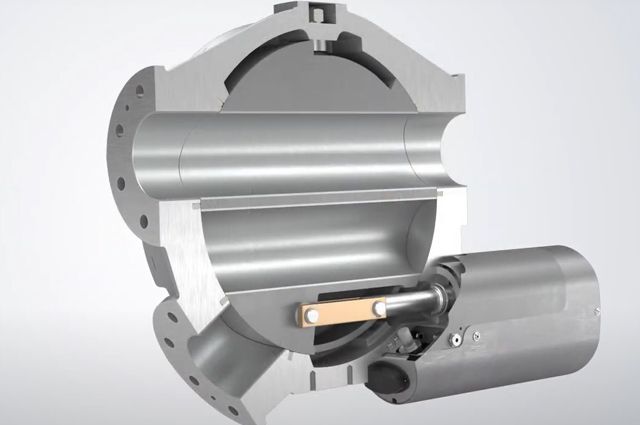

DVV Distributor and collector valve

The decisive detail in your process

Individual components that you do not necessarily associate with increased efficiency at first glance have nevertheless a positive influence on your overall process. Thus, the DVV dual-channel diverter valve with nominal diameters from 50 to 125 and a design pressure of 3.5 bar, is the right choice for your pneumatic conveying system, if you are looking for high reliability. Applicable as a distribution and collection diverter valve, for powder and granulates, the DVV also offers maximum flexibility.

Areas of application

Your advantages

- Compact construction

- High quality

- Low costs