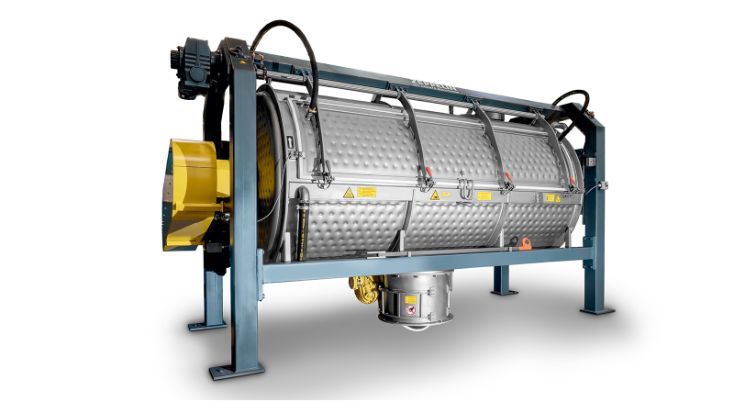

Zeppelin is setting the standards for mixing technology worldwide. With our HENSCHEL-Mixers® and MTI-Mixers, our mixing expertise in the plastics, chemicals, paint and varnish industries, as well as in the food sector, is exceptional. We offer the right solution for your mixing tasks, in terms of process, handling, and processing. In the context of a full process solution, the mixers are a byword for exceptional technical solutions and outstanding end product quality. The Zeppelin product portfolio includes the ideal heating, cooling, universal and container mixers adapted to your specific process. Our mixers stand for highest specific throughput, outstanding reliability, and unsurpassed service life. Manufacturing with high precision and from high-quality materials is a matter of course for us. The container mixers and wide range of cleaning options for the high intensity mixers provide you with a unique design for extremely fast and residue-free cleaning and a very fast product change. Our mixers meet international standards and feature optional explosion-protection measures to ensure outstanding safety.